MOLDING GYPSUM / CORNICE

KARTONPIYER is a plaster

used for the production of

decorative elements like

cornices.

Its working time enables easy

application with low wastage.

KARTONPIYER

is easy-to-mix.

Because it is a breathable

material, KARTONPIYER

helps create a healthier

environment by stabilizing

the humidity.

KARTONPIYER has

high strength and

surface hardness.

Because of its fine grainsize

KARTONPIYER produces a

smooth cast surface.

You can use KARTONPIYER to both make and fix plaster mouldings.

Pour water into a clean bowl. Sprinkle in KARTONPIYER until it just covers the water surface. Wait a few minutes, then mix until a homogeneous mortar is achieved. After mixing, the mortar is ready to be poured into the moulds. The mortar sets in approximately 30 minutes.

Cornices made from KARTONPIYER should be fully dry before being installed.

Clean your tools after use.

Never mix KARTONPIYER with any other product or material.

Do not add any water or plaster to the mortar after mixing

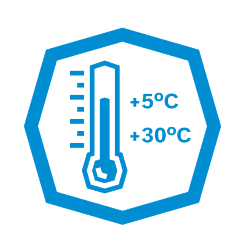

Do not use KARTONPIYER in temperatures below +5°C.

Dry and warm surfaces must be moistened before application.

Dry and hot facades must be heated before watering.

Store bags of KARTONPIYER in a dry environment, and stack no more than 20 bags high. Do not allow bags to be in contact with the ground or with moisture.

Use KARTONPIYER within 1 year of the date of manufacture.

Poor storage or exceeding the shelf-life may cause the physical properties of KARTONPIYER to deteriorate.

Water/Plaster ratio

Moulding ............. 7-7,5 L of water to 10 kg of KARTONPIYER

Bonding ............... 6-6,5 L of water to 10 kg of KARTONPIYER

Setting time starts ........................................ >8 minutes

Final setting time ........................................... 30 minutes

Compressive strength (min.) ............. 100 kgf/cm2 (4x4 block

Flexural strength (min.) ......... 45 kgf/cm2 (4x4x16 block)

Pass 200 micron sieve ........................................... %99.5

Pass 100 micron sieve (minimum) .......................... %95

Bulk density (powder) ............................ 750-800 kg/m3

Dry density ......................................... 1050-1100 kg/m3

Fire classification........................................................... A1

Reference standard ..................................... TDS-125-79

Type ........ B4/20/2 C1 Plaster For Fibrous Plasterworks

Type .................................. Polypropylene laminated bags

Weight ................................................................. 30 kg±%1

PROTECT FROM MOISTURE

FIRE RESISTANCE: A1

SOUND INSULATION: NPD

MADE IN TURKMENISTAN

FOR INTERIOR USE

BASE TEMPERATURE

THERMAL INSULATION: NPD

USAGE TIME 30 MINUTES